Concreting & Compaction Equipment Hire

Vibrating Rollers & Wacker Plate Hire

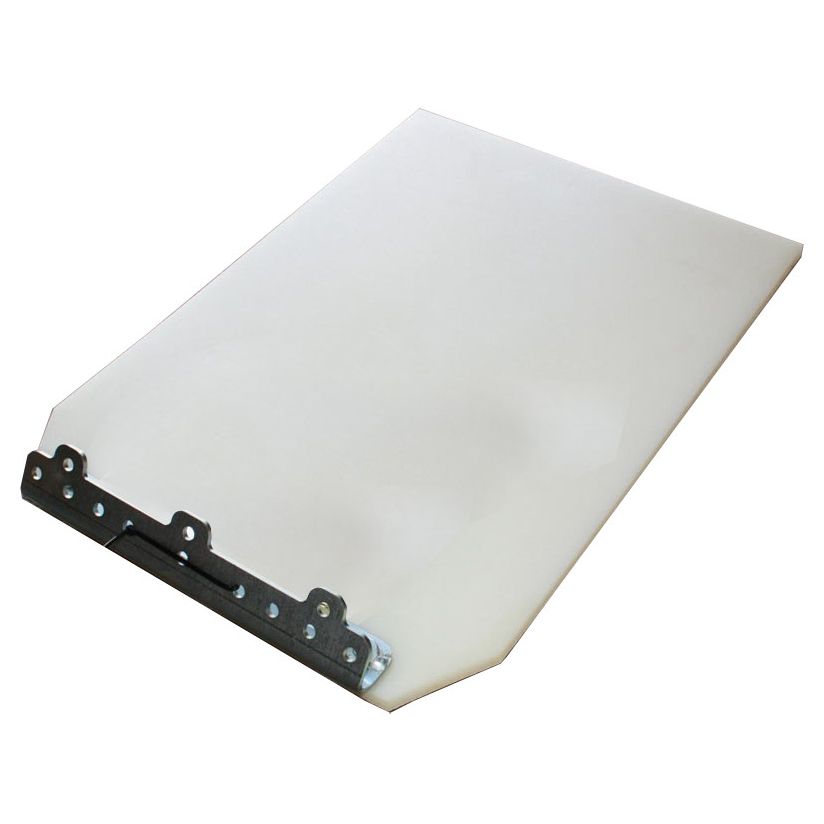

Vibrating rollers and wacker plates are essential equipment for any construction site where soil compaction is needed. Vibrating rollers are heavy-duty machines that are designed to compact soil and create a flat, even surface. They use a vibrating drum that is pushed over the soil, creating pressure and vibration that compacts the soil. Wacker plates, on the other hand, are smaller, handheld machines that are perfect for compacting smaller areas or hard-to-reach spaces. They use a powerful motor to create high-impact compaction, ensuring that the soil is firmly compacted and ready for construction.

We can deliver a range of vibrating rollers and wacker plates that are perfect for a variety of construction tasks, including roadworks, building foundations, and landscaping. With various sizes and models available, we have the perfect machine for every project. All of our equipment is built to the highest standards, ensuring that they are reliable, safe, and easy to use. Whether you’re a professional contractor or a DIY enthusiast, our vibrating rollers and wacker plates will help you get the job done quickly and efficiently.

OTHER PRODUCTS TO HIRE

Looking For Other Vibrating Rollers & Wacker Plate To Hire?

access the uk's largest digital supplier network

Over 2,000 Depots, And 900 Suppliers Across The UK.

Save money. save the planet.

95% of products we help source are delivered within 15 miles of our customer's projects.

That's 75% closer than the construction industry average of 60 miles.

Reduce wasted miles

We will always match your booking to the closest, available suppliers.

Expand your margins

Tackle overspending by leveraging a hyper-localised supply chain.

Hit your sustainability targets

Stipulate a radius to achieve your considerate constructor mandates.

Reach Net Zero by 2050

Zero emission options including electric equipment and recycled materials.

DIGITAL CONSTRUCTION SUPPLY CHAIN MANAGEMENT

Our Focus Is To Make Your Supply Chain More Efficient.

Reduce time spent sourcing equipment and suppliers.

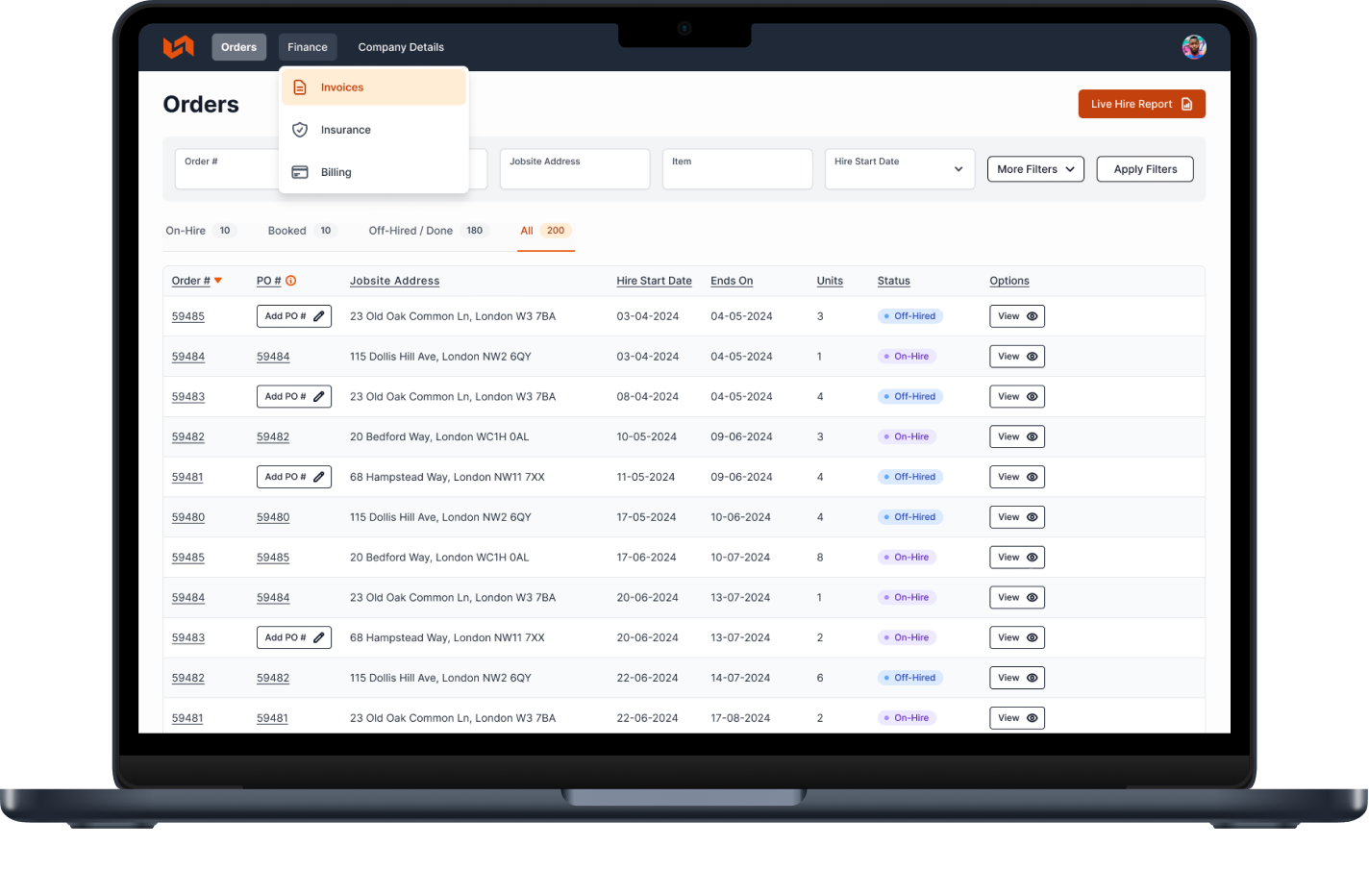

Finally, a solution for streamlining your procurement. In the YardLink platform, you can hire equipment, from any supplier, through a single account. Reduce time spent translating requirements from site, communicating with multiple suppliers and comparing non-standardised quotes. And the best part, it’s free.

Learn More

“Being able to manage all of our suppliers, in one platform, is a life-saver.”

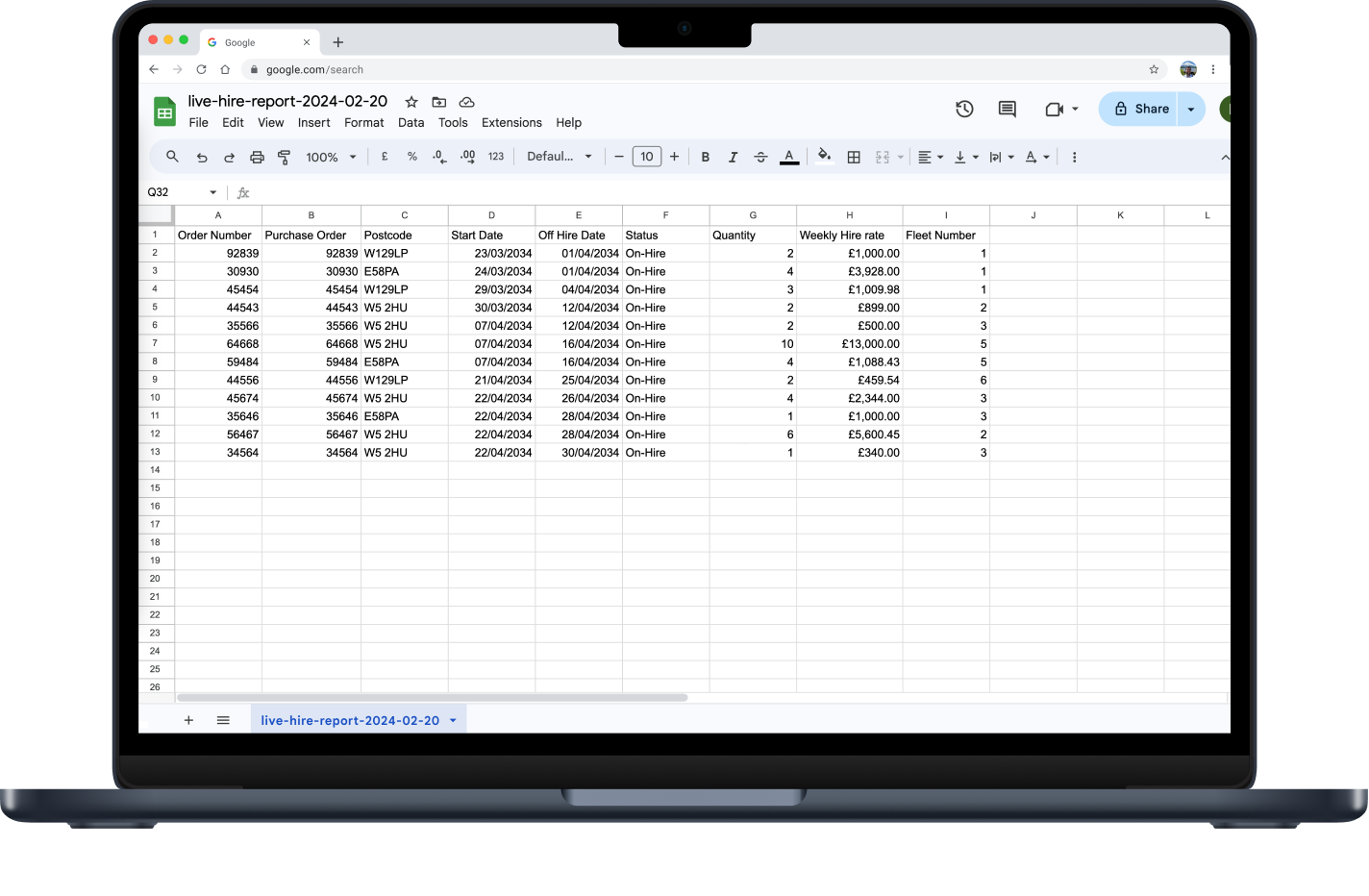

Always know what's on site. Never let inventory go to waste.

Gone are the days of requesting a live hire report from each supplier. Not to mention that they are no longer ‘live’ when they reach your inbox. In the YardLink platform, you can instantly generate a live hire report, across all suppliers, at a project level. Always know what’s on site, keep a close eye on equipment usage, and be aware of incoming deliveries and collections.

Learn More

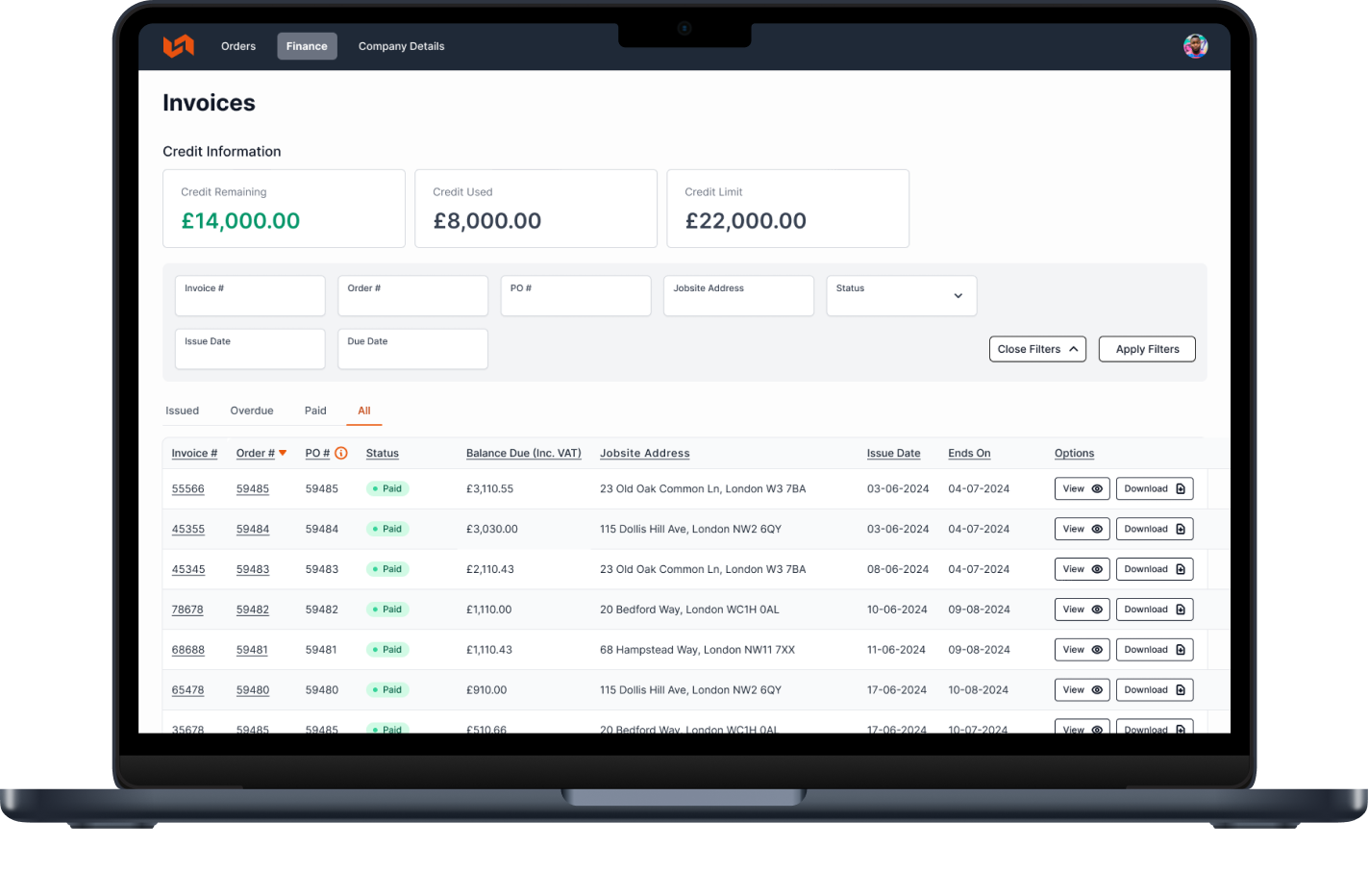

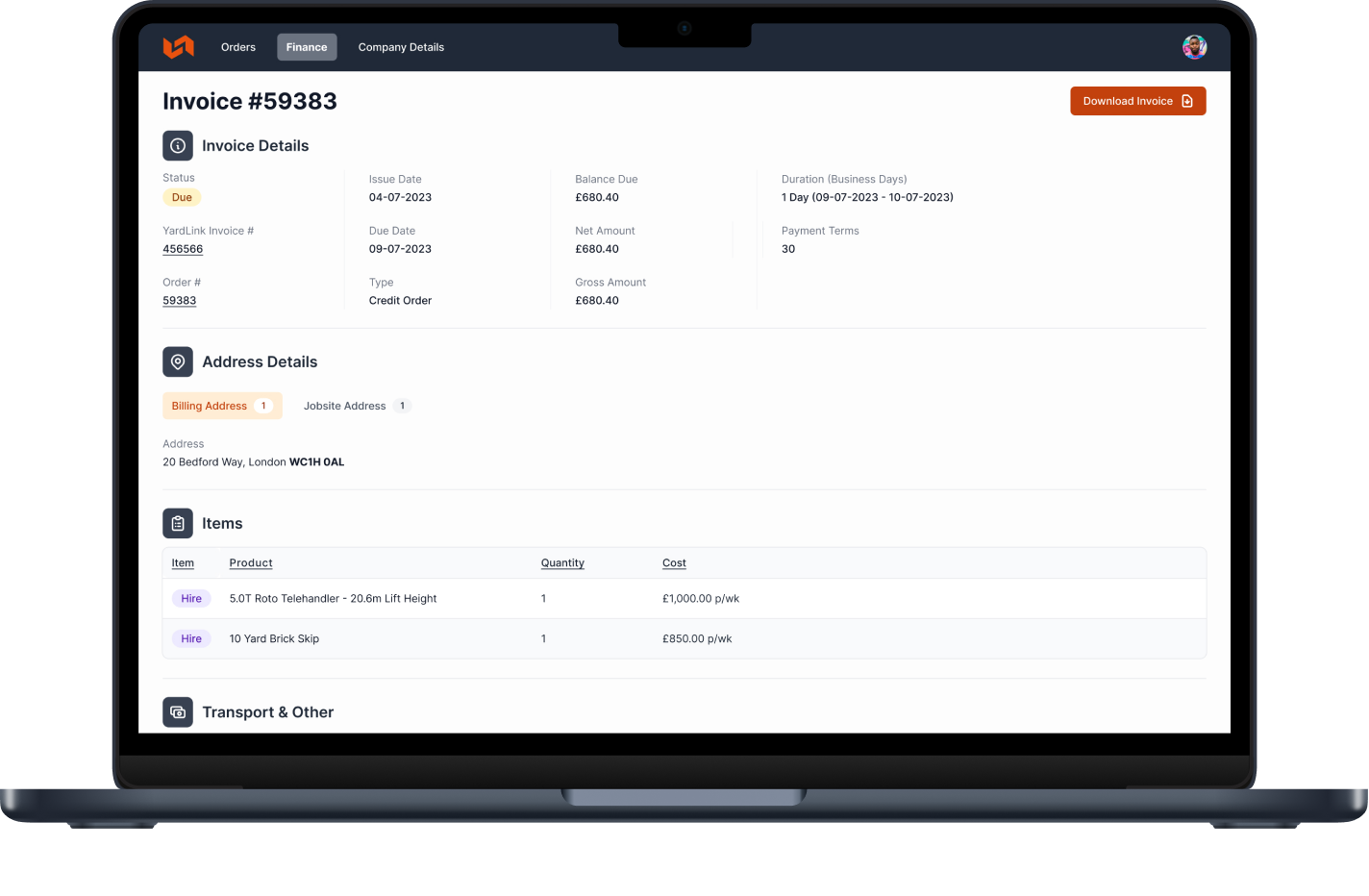

Keep the necessary paper trail, but manage it online.

Put the pen and paper down. Close the spreadsheet. And gain peace of mind with a digital paper trail through the YardLink platform. Standardised quotes, proof of delivery, and invoices (no matter the supplier), means fewer disputes and queries. Easier to manage and track. Our goal is to help you work smarter, not harder.

Learn More

Tackle overspending and spiralling budgets.

Wave goodbye to failed collections and aborted fees. Reduce the number of invoices in query and associated penalties. And, you no longer have to accept the heightened costs of using non-local suppliers. We always connect you with the closest available supplier. Less wasted miles and lower delivery costs.

Learn MoreTAKE THEIR WORD FOR IT

Construction Contractors Across The UK Rely On YardLink For The Best Equipment.

Vibrating Rollers & Wacker Plate Hire FAQs

Your Questions, Answered.

There are various types of wacker plates available, including forward plates, reversible plates, and remote-controlled plates. Forward plates move in one direction, while reversible plates can move forward and backwards. Remote-controlled plates can be operated remotely, which is beneficial for compacting in tight or hazardous areas.

When selecting a wacker plate, consider factors such as the compaction force, plate size, weight, engine power, fuel type (petrol or diesel), and the type of surface you'll be working on. It's important to choose a plate that suits the specific requirements of your project.

Wacker plates are designed for use on compactable surfaces such as soil, gravel, sand, and asphalt. They are not suitable for use on hard surfaces like concrete or tiled floors, as they may cause damage.

Yes, a vibrating roller can help level out minor unevenness or bumps in the surface. However, it is important to note that significant irregularities may need to be addressed before using the roller, as excessive variations can affect the compaction results.

The depth to which a wacker plate can effectively compact the material depends on various factors, including the type of material, its moisture content, and the specific machine being used. Generally, wacker plates can compact material up to several inches deep.

Yes, most vibrating rollers allow you to adjust the vibration intensity. This feature enables you to customise the compaction process based on the type of material and thickness of the layer being compacted. Consult the machine's manual for guidance on adjusting the vibration settings.

When using a wacker plate, always wear appropriate personal protective equipment (PPE). Ensure the work area is clear of obstacles and personnel. Avoid overexertion and take regular breaks. Never operate the machine on unstable or uneven ground. Follow the manufacturer's instructions and guidelines for safe operation.

blog